The Frequently Asked Questions

How much does it cost?

Earthbolt quotes a fixed amount per anchor for the installation and removal which includes 2 site visits. The price per unit is based on a sliding scale for the number of anchors required on the project.

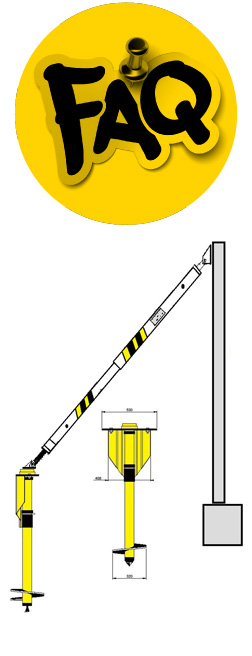

What depth is an Earthbolt installed to?

An Earthbolt anchor is screwed into the ground to a depth of 1350mm and electronically monitored for torque level to ascertain its kN loading. The Earthbolt safety anchor has been tested for load applications with a prop connection at 60 degrees to a WLL of 52kN and used for panels of up to 12.4 metres in height.

What do we need for a formal quotation?

Earthbolt requires the precast panel manufacturers MP1 MP2 or layout, including panel elevations to generate a quotation.

How long does it take to install/remove?

Depending on site induction time and ground conditions, the Earthbolt operations team will install enough safety anchors for 50 precast concrete panels in just over half a day. A maximum of 100 in a single day can be achieved with good conditions. Generally it takes half the time on site to remove the same number of anchors.

What if the ground is not suitable?

Earthbolt require a geotechnical report and with our knowledge of localities and associated ground conditions through experience we know where our product is suitable and where difficulties are going to be encountered. In difficult areas we make every effort to ensure installation with earlier site testing or predrilling pilot holes with a mining spec auger. There are particular localities that we will immediately advise you if our product is not suitable.

What equipment is used in the process?

Earthbolt uses current model 5.5t excavators with a customized planetary drive unit putting out over 18,000 Nm of torque to install and remove our product. Product is loaded and unloaded in stillage units via a current model skid steer or tracked loader and distributed around the project site as required. All machines are serviced regularly in accordance with the manufacturer’s guidelines by their Australian distributor.

Do mezzanine level offices and basement structures cause height issues during removal?

Generally no it is not an issue as removals can be done with our skid steer equipment so even access heights down to 2.2 metres are acceptable.

How long can we have them on site?

Our quotations allow the product to be installed on site for 35 days, after which the company reserves the right to charge a daily hire rate. It is generally rare for such cases to occur and no hire charges are applicable over the Christmas New Year period.

What bolts are required to connect brace or prop footings to an Earthbolt?

We recommend new flanged M20 bolts during lifting procedures. We also recommend that the builder or precast riggers supply M20 bolts to us to install when we install to keep all threads clean and protected making their lifting process easier.

Does Earthbolt have an EBA?

Yes, the company has an EBA and our employees are also financial members of the CFMEU. Earthbolt and its staff are also registered with cBus, Incolink and CoInvest.

Does Earthbolt have insurances?

Yes the company maintains current certificates on all insurances including WorkCover, Public Liability and Professional Indemnity for all its activities and products Australia wide.

What about underground services?

Before Earthbolt staff commence any installation during the site investigation it is the Site Managers responsibility to clearly mark any existing services to ensure no damage occurs. This has always delivered a problem free installation over the years.

What if the ground close to an anchor is disturbed?

If an anchor is subjected to additional earthworks i.e. trenching within 1500mm or major storm erosion Earthbolt must be notified immediately for our Engineers opinion.

How much lead time do we need to give Earthbolt?

Although we recommend giving us at least 5 days’ notice prior to an installation and removal to ensure our scheduling and booking system runs smoothly it’s not a perfect world especially with weather etc. in the commercial construction industry. For this reason we react as fast as possible to any request and more often than not if a request is made late one day it is not unusual that we are on site first thing the next morning. We move heaven and earth to ensure first class customer service.

Has an Earthbolt precast propping anchor ever failed?

No. With leading edge design and a failsafe collar incorporated into its design mechanism to withstand lateral and uplift forces applied via severe wind loading no Earthbolt product after 100,000 installations has ever had its structural integrity compromised.